It’s predicted that by 2026, 95% of companies will continue to use outdated supply chain models and that will prevent them from achieving end-to-end resiliency in their supply chains. In addition, the electric vehicle (EV) market is set to grow at a CAGR of 33.6% from 2024 to 2030, meaning that robust inventory management is more important than ever to help manage this increase in demand.

Despite the significant market opportunity, rising material and energy costs alongside disrupted trade routes are hindering the progress of EV OEMs. However, distributors are constantly adapting to these challenges and optimizing their inventory management processes to mitigate supply chain risk so their partners can meet demand.

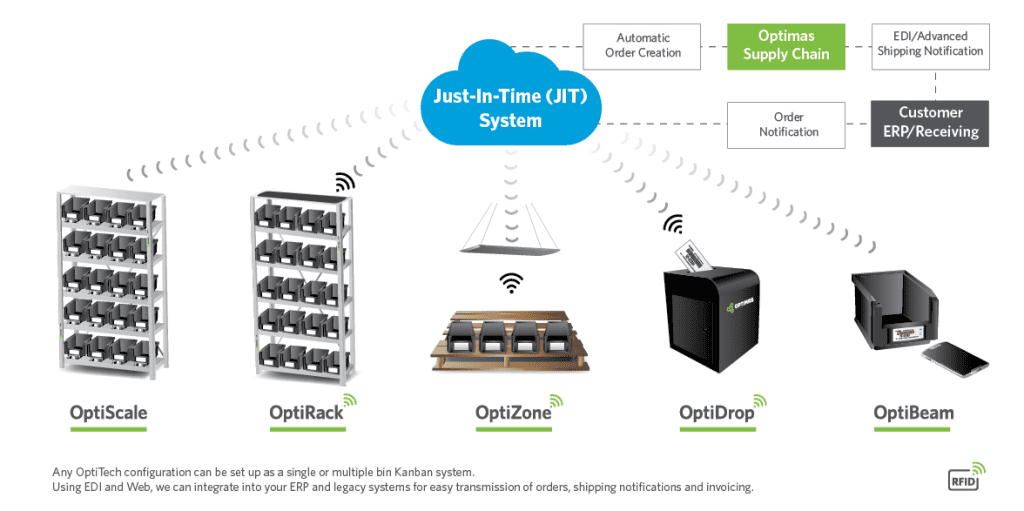

With over 100 years of experience manufacturing and distributing fasteners to a range of industries, including EV, Optimas is an expert at reducing risk and elevating output. Employing advanced cloud-based technology, our OptiTech inventory management solutions ensure availability and boost operational efficiency.

Master Your Data Management

When it comes to assessing supply availability, EV OEMs must have good, clean supply chain data, transparent and realistic demand forecasts and production schedules.

Automated collection of usage data, in real time, will bring inefficient inventory management processes into focus and enable EV OEMs to make smarter decisions and re-task teammates to higher value activities. This can be done in one of two ways:

- Designating a person or department to oversee supply chain data

- Working with a third-party supply partner to manage that information and apply it to current inventory management processes

Supply partners, like Optimas, have experts who can assess current processes and identify an EV OEMs specific need for a digital inventory management system. From learning about their ideal replenishment intervals to understanding typical quantities for reordering, these experts can find solutions tailored for their requirements.